close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

Carrageenan Free Almond Milk is gaining popularity as consumers seek cleaner, healthier plant-based alternatives. In this article, we explore market trends, formulation tips, and how to create smooth, shelf-stable almond milk without carrageenan. From alternative stabilizers to texture optimization and nutrient retention strategies, we cover everything manufacturers and home makers need to know. Whether you’re health-conscious, vegan, or curious about “free-from” beverages, this guide helps you understand the growing demand for carrageenan-free almond milk and how to make it taste great.

Carrageenan is a natural polysaccharide extracted from red seaweed and has been used in food systems for centuries. It originated in coastal regions where seaweed was traditionally added to foods for thickening and texture improvement. Today, it is widely applied in modern food manufacturing because it delivers reliable functional performance while remaining plant-derived. Its marine origin and renewable sourcing make it attractive for dairy-free and vegan formulations.

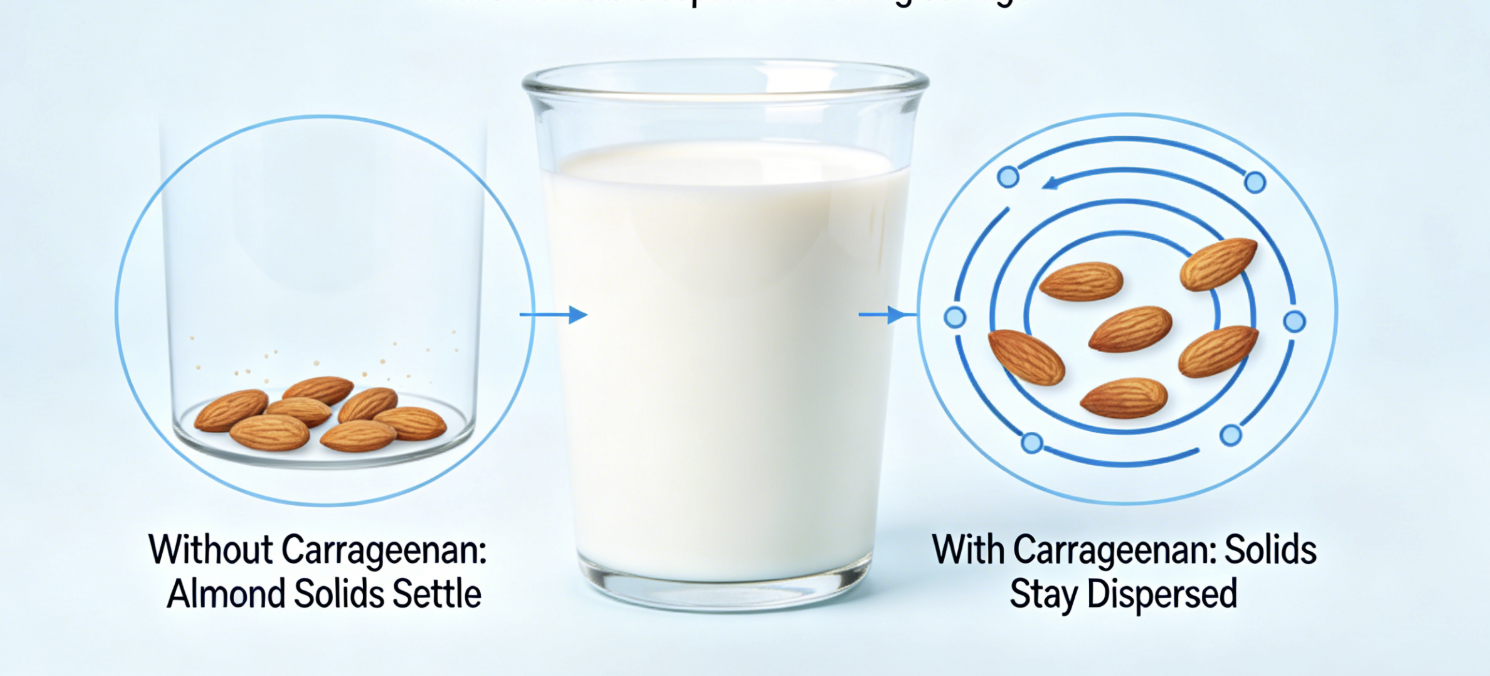

Almond milk is primarily composed of water, which creates formulation challenges related to separation, texture, and nutrient distribution. Carrageenan addresses these challenges by performing multiple functional roles within the beverage system.

Carrageenan helps keep almond solids evenly dispersed throughout the liquid, reducing visible separation during storage. It improves product uniformity and appearance, allowing almond milk to remain consistent on the shelf without requiring excessive shaking. This stabilization effect supports both consumer convenience and brand perception.

By interacting with water and proteins, carrageenan contributes to a smoother, creamier mouthfeel. It enhances body and viscosity without adding fat, helping almond milk better mimic the sensory experience of dairy milk. Many consumers notice this difference when comparing thicker, more satisfying plant-based milks to thinner alternatives.

In fortified almond milk, carrageenan plays an important role in suspending added vitamins and minerals such as calcium and vitamin D. It prevents these heavier nutrients from settling at the bottom, ensuring more consistent nutritional value in every serving.

| Functional Role | Impact on Almond Milk |

|---|---|

| Stabilization | Prevents separation and improves visual consistency |

| Texture enhancement | Adds creaminess and improves mouthfeel |

| Nutrient suspension | Keeps added vitamins and minerals evenly distributed |

As demand for plant-based milks increased, manufacturers faced the challenge of delivering products that matched dairy milk in texture, stability, and shelf life. Carrageenan quickly became popular because it performs well at low usage levels, withstands heat treatments such as UHT processing, and supports long shelf stability. It also fits plant-based labeling expectations and works consistently across large-scale production, making it a practical choice for many almond milk brands during the early growth of the dairy-free market.

Many consumers link food choices to gut comfort and long-term wellness. Carrageenan often appears in online discussions around digestion and inflammation. Some studies focus on degraded carrageenan, a chemically altered form not approved for food use. Food-grade carrageenan differs in structure and behavior, yet the distinction rarely reaches shoppers. They tend to group all forms together. This gap between scientific nuance and public understanding strongly influences buying behavior. When people feel uncertain, they choose avoidance. For almond milk, that often means selecting carrageenan free options.

Key perception drivers include:

Concern over digestive sensitivity

Confusion between food-grade and degraded carrageenan

Preference for “better safe than sorry” ingredient choices

Clean label means simple ingredients people recognize and trust. In plant-based beverages, it usually points to short lists and familiar names. Many shoppers scan labels quickly. They skip products with ingredients they cannot pronounce or explain. Carrageenan, even though seaweed-derived, feels unfamiliar to some. Social media amplifies these feelings. Wellness influencers, food bloggers, and short videos shape opinions fast. They often promote minimal processing and kitchen-style ingredients. Brands respond by reformulating almond milk to match these expectations.

Common clean-label signals in almond milk:

Fewer total ingredients

No stabilizers or emulsifiers listed

Clear sourcing and processing claims

| Clean-Label Expectation | Consumer Reaction |

|---|---|

| Short ingredient list | Higher trust |

| Familiar ingredients | Faster purchase decisions |

| Transparent labeling | Stronger brand loyalty |

Retailers play a growing role in ingredient acceptance. Some introduce internal “free-from” lists influenced by consumer advocacy groups. Carrageenan sometimes appears on these lists, especially in natural and organic retail channels. Brands adjust formulations to secure shelf space. Regional views also differ. The ingredient remains widely accepted in many global markets. In North America and parts of Europe, scrutiny stays higher. They reformulate to align with local expectations. We see carrageenan free almond milk becoming more common as a result.

Factors shaping market pressure include:

Retailer ingredient guidelines

Advocacy group campaigns

Regional regulatory interpretations

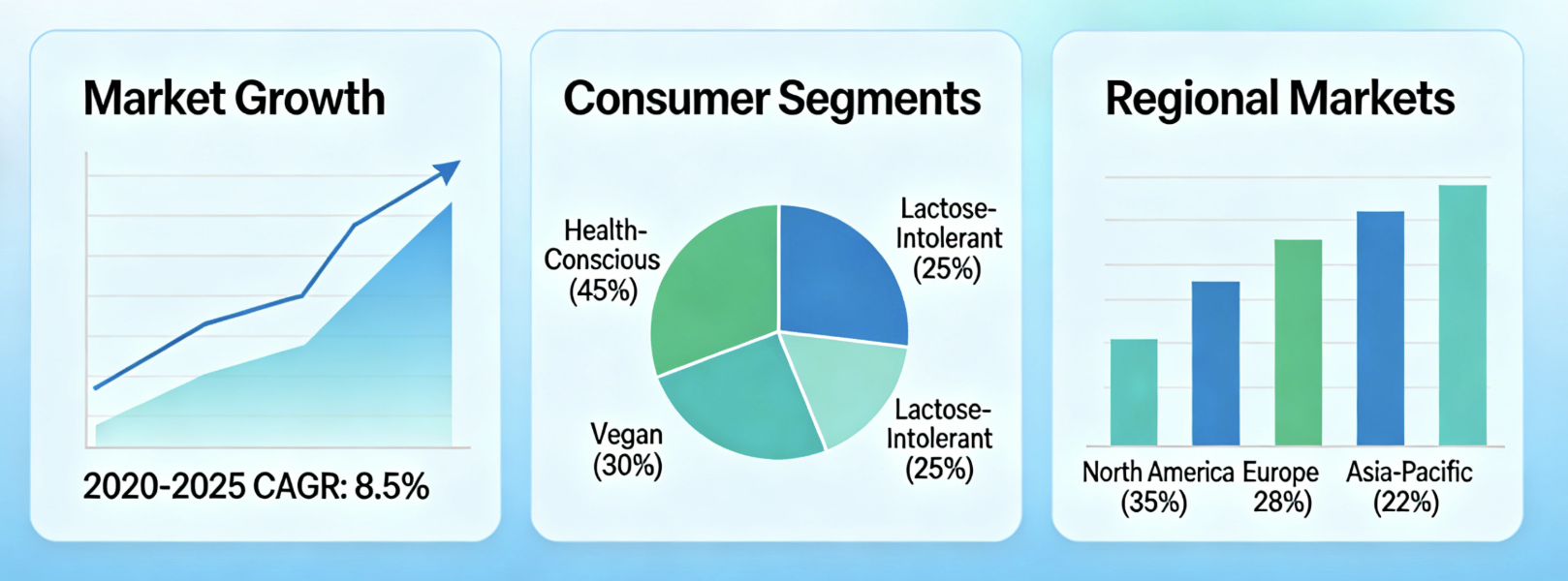

Carrageenan free almond milk continues to gain attention across global plant-based beverage markets. Shoppers increasingly connect ingredient choices to digestion, transparency, and long-term wellness goals. This shift supports strong growth for “free-from” almond milk lines.

Brands expand allergen-friendly portfolios to attract cautious buyers. Many position these products as premium offerings. Higher prices feel justified when labels promise simplicity, clean sourcing, and minimal processing. We now see carrageenan free options moving from niche shelves into mainstream retail.

Key growth signals include:

Rising global demand for free-from almond milk

Expansion of allergen-aware product ranges

Premium pricing tied to clean-label value

Different consumer groups drive demand for carrageenan free almond milk. Health-conscious shoppers often avoid ingredients they associate with digestive discomfort. Vegan and plant-based consumers value minimal processing and plant-first positioning. Parents and families seek safer-feeling products for children.

Digestive-sensitive audiences look for almond milk that feels lighter and easier to tolerate. Clean-eating followers prioritize short ingredient lists and recognizable names. They influence trends through word-of-mouth and online communities.

| Consumer Segment | Primary Purchase Motivation |

|---|---|

| Health-conscious | Gut comfort and transparency |

| Vegan and plant-based | Natural formulation alignment |

| Parents and families | Ingredient safety perception |

| Digestive-sensitive | Avoidance of potential irritants |

| Clean-eating | Simplicity and label clarity |

Regional dynamics shape how carrageenan free almond milk develops worldwide. In North America, clean-label leadership drives strong private-label growth. Retailers promote simple ingredient claims and respond quickly to consumer feedback. Europe shows high regulatory awareness and rising demand for organic almond milk. Shoppers there closely read labels and trust certification schemes.

Asia-Pacific markets move differently. Innovation leads growth as new plant-based beverages appear. Almond milk adoption increases, especially in urban areas. Brands experiment with local flavors and lighter textures to match regional preferences.

Removing carrageenan changes how almond milk behaves. We need other systems to keep particles suspended and texture smooth. Each option brings different strengths, costs, and processing needs. Many brands test blends rather than relying on a single stabilizer.

Common alternatives include:

Gellan gum: Strong suspension power at low dosage, clean mouthfeel

Locust bean gum: Adds body and creaminess, often paired with gellan

Guar gum: Improves viscosity quickly, sensitive to overuse

Xanthan gum: Stable across temperature ranges, slightly slippery texture

Starch-based systems: Familiar labeling, softer structure

Blended hydrocolloid systems: Balanced texture, improved stability

| Stabilizer Type | Key Benefit | Watch-Out |

|---|---|---|

| Gellan gum | Excellent suspension | Needs precise dosing |

| Locust bean gum | Creamy texture | Hydration time |

| Guar gum | Fast thickening | Can feel heavy |

| Xanthan gum | Process stability | Mouthfeel risk |

| Starch systems | Simple label | Limited shelf stability |

Texture starts long before stabilizers. Almond milk without carrageenan depends heavily on base formulation and processing control. Fat content plays a big role. More fat increases creaminess and masks separation. Almond solids matter too. Higher almond content improves body and natural opacity.

Key texture tools include:

Fat content adjustments using plant oils or nut oils

Almond solids optimization for body and flavor

Homogenization techniques to reduce separation

Particle size control to improve mouthfeel

Smaller particles feel smoother. They also stay suspended longer. Homogenization pressure needs tuning. Too low causes separation. Too high damages proteins and flavor.

Fortified almond milk creates extra challenges. Calcium and vitamins tend to sink or clump. Without carrageenan, dispersion strategy becomes critical. We often rely on fine particle minerals and controlled shear during mixing. Emulsion stability matters even more in clean-label formulas.

Practical approaches include:

Using micronized calcium sources

Pre-dispersing vitamins in oil or water phases

Applying high-shear mixing early in processing

Matching stabilizer choice to mineral load

| Nutrient | Common Challenge | Typical Solution |

|---|---|---|

| Calcium | Sedimentation | Fine particle size |

| Vitamin D | Phase separation | Oil pre-dispersion |

| Vitamin A | Stability loss | Controlled heat |

| Vitamin E | Uneven distribution | Emulsion support |

Shelf life expectations depend on processing method. UHT almond milk demands stronger stabilization. Refrigerated products allow simpler systems but shorten distribution windows. pH control plays a quiet role. Slight shifts affect protein behavior and microbial growth. Packaging choice also matters. Light and oxygen exposure influence flavor stability and vitamin retention.

Key factors teams watch closely:

UHT versus refrigerated formulation design

pH control for microbial stability

Heat treatment impact on texture

Packaging compatibility, cartons or bottles

These choices shape how carrageenan free almond milk performs, both on shelves and in consumer kitchens.

A: It can be perceived as healthier by consumers, especially those concerned about gut health or preferring clean-label products, though overall nutrition depends on almond content and fortification.

A: Yes, without carrageenan, almond milk is more prone to separation, requiring alternative stabilizers or homogenization techniques to maintain uniform texture.

A: Gellan gum, locust bean gum, guar gum, xanthan gum, starch-based systems, or blended hydrocolloids effectively stabilize and thicken almond milk.

A: Yes, with UHT processing, proper pH control, and alternative stabilizers, it can remain shelf-stable without separation.

Carrageenan Free Almond Milk is reshaping how we think about plant-based beverages, offering cleaner labels and gentle digestion without sacrificing creaminess or stability. Consumers are clearly drawn to products that balance taste, nutrition, and transparency, creating exciting opportunities for innovators in the dairy-free market.

At Megafood (Shanghai) Health Technological Co., Ltd, we specialize in supporting manufacturers with high-quality ingredients and formulation guidance to craft premium, carrageenan-free almond milk. Explore our solutions and bring smoother, healthier plant-based options to your customers today!

Pneumatic pouring test machine is a new pouring equipment used in the development of laboratory confectionery. The working power of the machine is compressed air, and the whole working environment is hygienic and clean, which meets the production requirements of food hygiene. The machine is controlled by human pneumatic, touch screen operation, compact structure, stable performance. It is an ideal experimental equipment for pouring gelatin, pectin and carrageenan gummy candies.

Information

+86-21-64883956

+86-13916430454

Copyright ©️ Megafood ( Shanghai ) Health Technological Co. , Ltd Technology by leadong.com